I created this website to broadcast to the public my growth over the last three months in Writing for Engineers. I hope you enjoy its content!

Excerpts From my Works

Excerpt 1:

Abstract

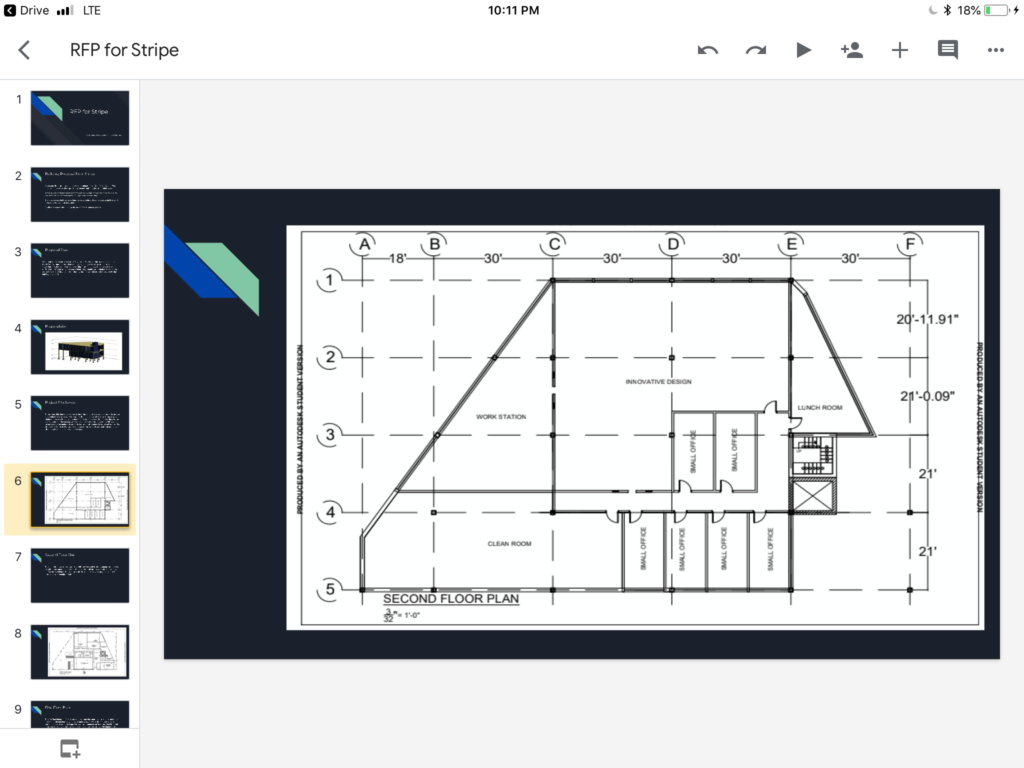

Our team of the best design professionals and engineers at Leonce Architects and Engineers, LLC. have constructed a design for your new Stripe Office Facility located at 101 Jefferson Avenue. Our design incorporates all office space requirements, alongside a concretized perspective from the team. The designers and engineers at Leonce Architects and Engineers, LLC. have designed a facility that integrates all desired office space necessities, while ensuring all zoning, building, and LEED requirements have been met. The design of the building guarantees accessibility from multiple entrances, but at the same time ensures absolute control of the building alongside the safety of passersby and employees. In order to create a new environmental fusion of business and lifestyle development for entrepreneurs, our design team have created a structure that is sustainable yet modern at the same time. The facility will have many different modern structural concepts, such as a fully glassed innovative design area to ensure natural light and a modernistic vibe.

On the contrary, smaller compact soundproof offices will be created to ensure maximum productivity and isolation. Our design team has created the design to assure reasonable building and maintenance costs by simply designing a structure which gets rid of jargon. The design team has created multiple parking spots across the street, and several bike racks which were strategically placed next to the building to improve traffic flow. At Leonce Architects and Engineers, LLC. we thrive for making our projects eco-friendly, which is why we have left a vast amount of space by the northern and eastern property lines to create a stress-free garden for employees. The empty spaces on the two sides of the infrastructure will consists of a laidback seating area amongst refreshing trees and other landscaping features. Since we put the ease of our clients first, we have incorporated a drop-off/pick-up drive through on the western side of the facility. This paved pathway, spaced enough for trailer trucks, will be the hub for supply deliveries and personnel drop-off throughout the day while maintaining the flow of traffic.

Excerpt 2:

How Concrete Is Made

In Contrary to popular belief, concrete and cement are not the same thing; cement is actually just one component of concrete. Concrete is mixture of three basic components: water, aggregate and Portland cement along with a long process of wetting and drying to reach its final form.

Here’s how it is made…

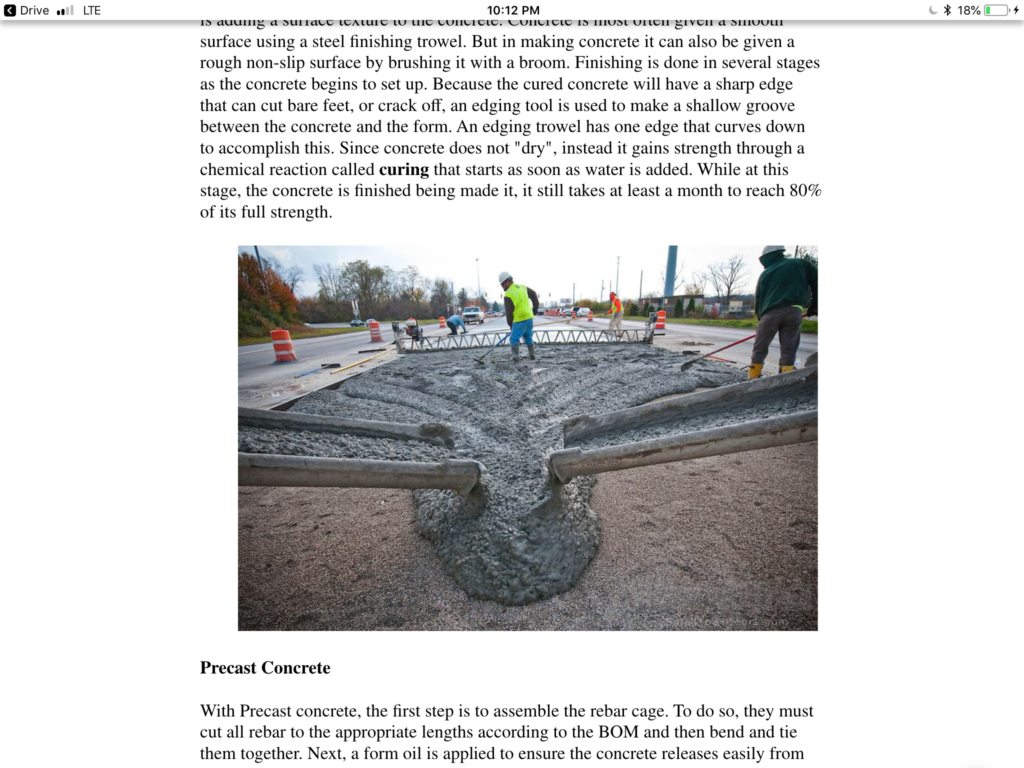

Sitecast Concrete

Sitecast concrete starts off by creating a frame that holds concrete in the shape that is desired for the finished product. Once the desired form reaches its capacity apply a screed board. A screed, normally a little longer than the width of the form, used to level the wet concrete even with the top of the form. After this, the wet concrete must be agitated by using a float. It is a small smooth board with a handle that is used to agitate the wet concrete to sink rocks below the surface, eliminate air pockets, bring water up to the surface, and to smooth the concrete. The final stage of making concrete is adding a surface texture to the concrete. Concrete is most often given a smooth surface using a steel finishing trowel. But in making concrete it can also be given a rough non-slip surface by brushing it with a broom. Finishing is done in several stages as the concrete begins to set up. Because the cured concrete will have a sharp edge that can cut bare feet, or crack off, an edging tool is used to make a shallow groove between the concrete and the form. An edging trowel has one edge that curves down to accomplish this. Since concrete does not “dry”, instead it gains strength through a chemical reaction called curing that starts as soon as water is added. While at this stage, the concrete is finished being made it, it still takes at least a month to reach 80% of its full strength.

For project 3, as a team we were ask to create an innovated design for a tech company’s program for a new office building. After research and applied science we brought to are client a double glazed window, which is a window that serves dual purpose as a heat reducer and amplifier depending of the desire of the system. Myself, serving the role of Project Manager, along side our team of architects, engineers, accountants have created a schedule plan with allowance to not only purchase all materials needed but also design and build. As a team, there was constant communicating, a solid check and balance system so all voice heard and used. We met in person as a group not to only discuss the order in which produces the best version of our presentation to the client but also be on the same page with exactly what we created and how it will be beneficial to our client.

With all that being said, I believe our final presentation deserve a 95% with room for improvement being a more in-depth presentation of the project’s allowances.